Micro Power Packs

Key data

HPI benefits from an exclusive motorization, as a result from an automotive technology which helps to obtain higher power with an improved service and minimum overall dimensions.

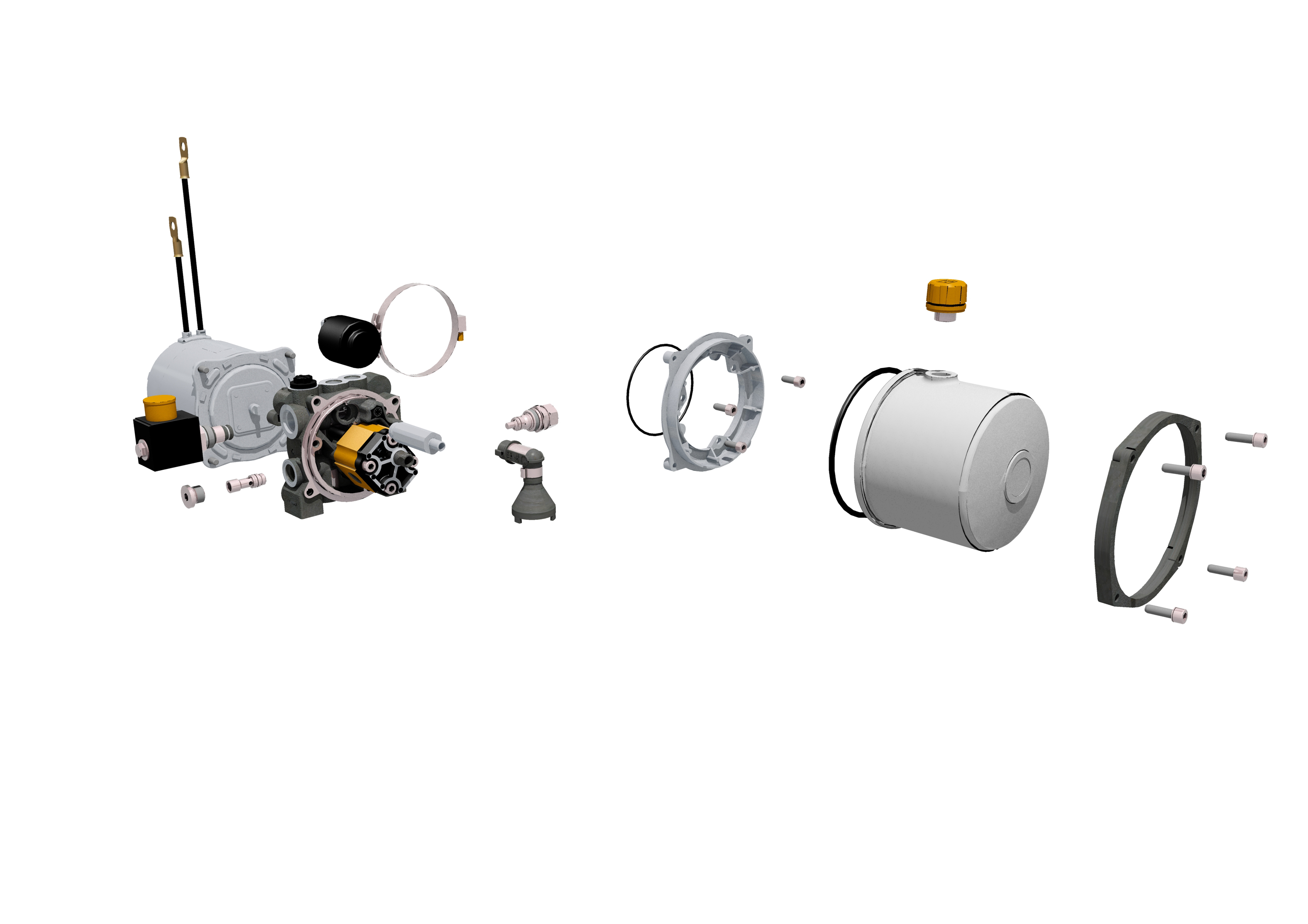

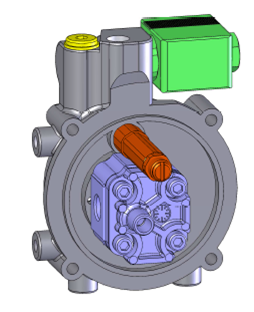

To ensure a higher reliability and maximum flexibility, HPI power packs are designed around a system of cartridges which fits directly into the support.

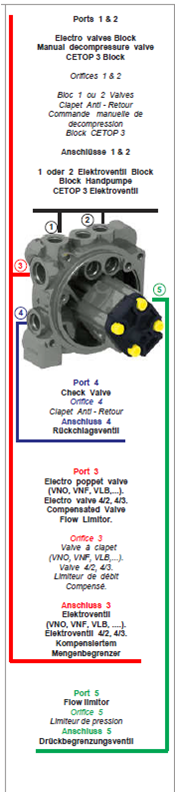

- The pressure relief valve and the check valve are two cartridges inserted into the support which is easy to disassemble for modification or maintenance.

- Poppet valves such as VNF, VNO, VLB, 4/2, 4/3 and even proportional valves can be fitted directly into the support without a block

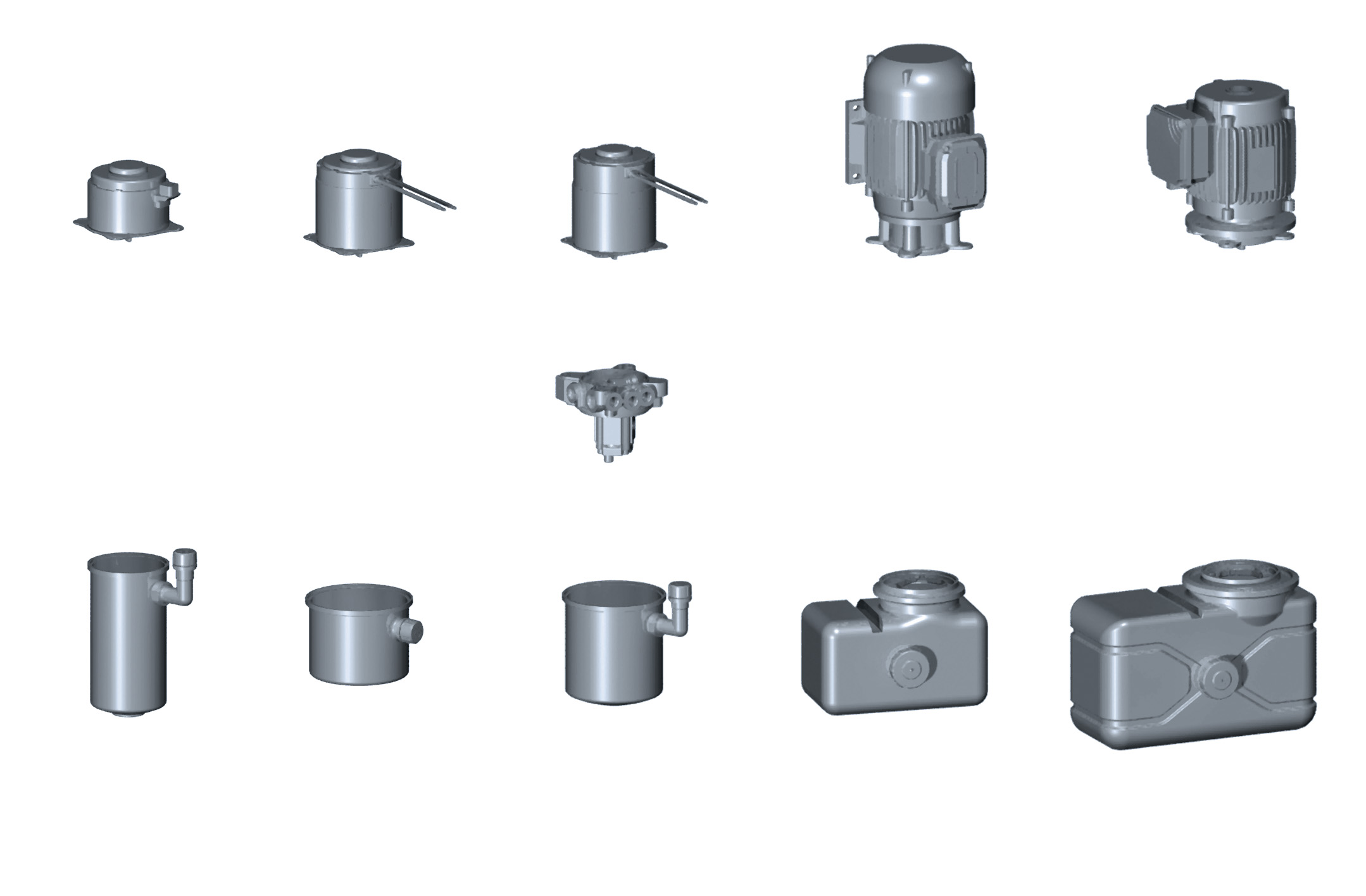

HPI micro power packs are available:

- In direct or alternative, single and three-phase currents: with power ranging from 0.4 to 1.2kW, very compact; e.g. our 400 W motor is only 78 mm long with a diameter of 100 mm!

- Direct current:

- Flow: 4 to 9 l/min

- Maximum pressure : 280 bar

- Alternative current:

- Flow: 0.4 to 1.2 l/min

- Maximum pressure: 280 bar

- Tanks : 0.5 to 6.3 L

The HPI power pack range meets your specific needs with 3 families of products :

- Micro power packs 2G

- Micro power packs 3G

- Silent micro power packs

A turn-key solution

Our micro power packs 2G have an exclusive motor originating from automotive technology. They are very reliable and competitive. The unique design of the support, especially designed for pallet truck applications, directly incorporates the pressure relief valve and the functional valve without the need to add additional blocks. The power pack is compact and optimized in order to address physical size challenges.

HPI offers a turnkey solution which has proved its worth!

- Maximum pressure : 250 bar

- Direct current

- Power: 0,8 and1,2 kW

- Support with pressure relief valve and check valve

For more information, please refer to our detailed technical sheets.

A product of high technology

HPI’s third generation of micro power packs are based on a 100% modular design which incorporates exclusive elements:

- An exclusive HPI motorization available in direct or alternative current

- A die cast support able to directly incorporate functions without the need of blocks

- A high efficiency 0 pump series which enables to increase the service rate of the power pack: pump capacity from 0,25 to 2,00 cm3/rev.

- The possibility of creating complex systems by fitting valves on a set of ports and a cartridge valve cavity with integrated electronic control

- A wide range of standard tanks from 0,5 to 6,3 liters capacity

The design of our micro power pack 3G facilitates the design and construction of complete hydraulic systems featuring:

- A compact design

- A support enabling the production of complex applications by integrating hydraulic functions into a set of ports and a cartridge valve cavity.

- The possibility of directly assembling a simple single or a double-acting circuit on the support!

- The integration of electronic control for power pack valves

- A range of standard tanks resulting in the design of power packs with the smallest possible overall dimensions

For more information, please refer to our detailed technical sheets.

For pallet truck applications

-

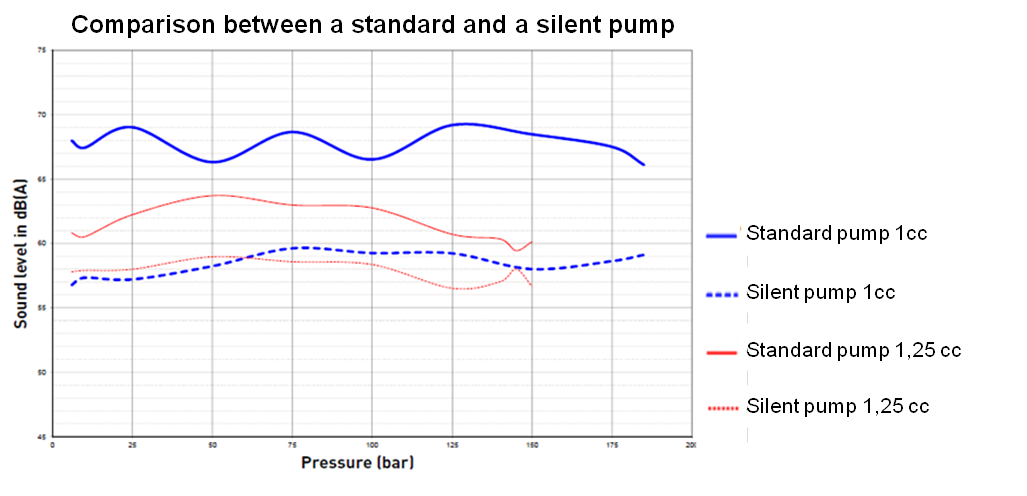

- Noise reduction by an average of -10dBA

- Operating frequency ranges adapted for optimized working conditions for the user

- The 22-tooth helical profile on series 0 pumps, unique for that size of pumps

- Capacities available are 1,00 – 1,25 – 1,50 – 1,70 – 2,00 cc/revfor operating pressures from 125 to 250 bar

Noise reduction is indeed becoming the real challenge for today’s industrial market. Market competitiveness and new European regulations in the material handling sector, particularly for pallet trucks, are such that suppliers are compelled to develop new technologies and meet enhanced customer requirements. Acoustic nuisances have several origins: pump hydraulic pulsations being propagated through hoses and pipes which then affects the truck frame structure (structure-borne sound) and aerial noise (rotation frequency of an electric motor or a pump) which can be contained by an acoustic cover.

Very compact, our Silent Pump technologies result in amazing noise pollution reductions.

.

Comparison of 1,00 cc/rev and 1,25cc/rev capacities using standard and silent pinion technology. The tests were realized in HPI’s own anechoic room on a power pack with a 1,2kW motor.

We worked closely with our Blois (France) production site R&D Department, dedicated to automotive applications, to develop a unique side plate profile, which is the component that contributes to noise reduction. We took advantage of our technology developed over several years for steering systems adapted it to our material handling sector applications. We applied our technology, thanks to new tests and research development, and enhanced it in order to cover a wider range of capacities and pressures in accordance with our customer requirements.

In order to minimize hydraulic pulsations, we designed a specific helical tooth profile with a suitable propeller angle and increased the number of teeth of the pinions from 12 to 22.

Acoustic results show that the noise level has been reduced by an average of -10 dBA, when compared with a standard external gear pump. The new HPI Silent Pump is also characterized by a much more pleasant sound when in use. Indeed, the operating frequency ranges have been adapted for user optimized working conditions. The 22-tooth helical profile on series 0 pumps, unique for that size of pumps, significantly reduces hydraulic pulsations. The capacities available are 1,00 – 1,25 – 1,50 – 1,70 – 2,00 cc/rev for operating pressures from 125 to 250 bar.

All our Silent Pumps are available on our micro power packs 2G and will soon be available on our 3G and 4G power packs.